COMPLIANCE

The Golden Thread Approach

Our certified ISO9001 Quality Management System demonstrates our ability to provide consistent service delivery in line with agreed performance measures. Full QC Audit is carried out throughout the design process, manufacturing, delivery, and installation process.

We store Golden Thread information on A Site which is a cloud-based Common Data Environment global server network that protects all our data against failure and all project data is replicated every 30 minutes to other data centers for Tier 4 disaster recovery.

The golden thread information management approach will apply through design process, manufacture, installation, and completion/handover. It will be stored, managed, maintained, and retained in line with the below golden thread principles:

- Accurate and Trusted

- Longevity, durability and shareability of all information stored

- Secured

- Simple to access

- Single source of truth all information being stored in one place

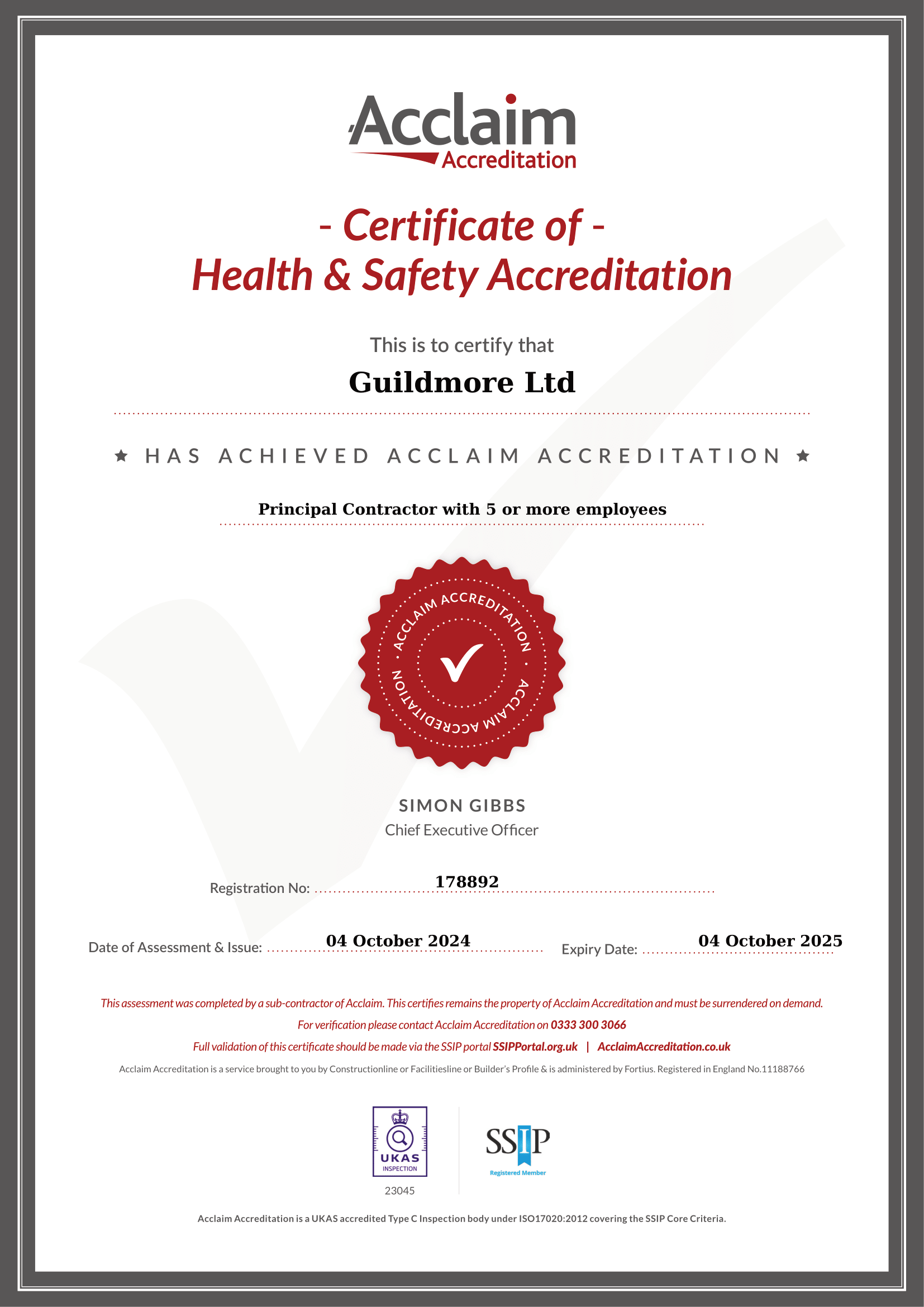

Health & Safety

We will use our four-point collaborative system of risk management (shown to Left) to identify risks during preconstruction and manage/mitigate in delivery

- Risk identification, including those identified at the bid stage, i.e., scaffolding, vehicle movements, public access to businesses within the property

- Risk Analysis, collaboratively with all stakeholders

- Method Statements (MS) and SSoW, to manage/mitigate risks

- Regular reviews/adjustments, to ensure mitigation remains effective.

1. Risk Identification:

Carry out a full investigation of site conditions during preconstruction and additional new risks from changes in site usage, access, and security

2. Risk Analysis

Collaboratively undertaken with Southark, Supply Chain, and our SHE Advisor, against each risk. Risks will be logged onto a Risk Register with clear allocation/responsibilities for mitigation/on-going management and assessment

3. METHOD STATEMENTS (MS) AND SAFETY SYSTEMS OF WORKS (SSOW)

These will be provided for the management of each risk. MS/SSOW for delivering the scope works will be updated to reflect conditions and constraints of the project. Training/instruction will be given to staff/supply chain through inductions/TBT/Daily Safety Briefings

4. REGULAR REVIEWS

On each risk item throughout preconstruction/delivery. Lessons learnt information review mitigations of on- going risks and best practice.

Carbon Reduction Plan

Our Carbon Reduction Plan is dedicated to minimising our carbon footprint by using eco-friendly practices, renewable energy, and sustainable materials. We aim to reduce emissions, enhance energy efficiency, and promote green construction techniques. Join us in building a sustainable future.

Modern Slavery Policy

Guildmore is committed to the highest standards of ethical conduct and integrity in our business practices. We recognise that modern slavery, including human trafficking, forced labour, and other forms of exploitation, is a serious global issue that requires immediate and sustained action. We are dedicated to preventing and addressing any form of modern slavery within our business operations and supply chains.

Discuss Your Next Project With Guildmore

Feel free to get in touch with our dedicated team to explore personalised construction strategies.